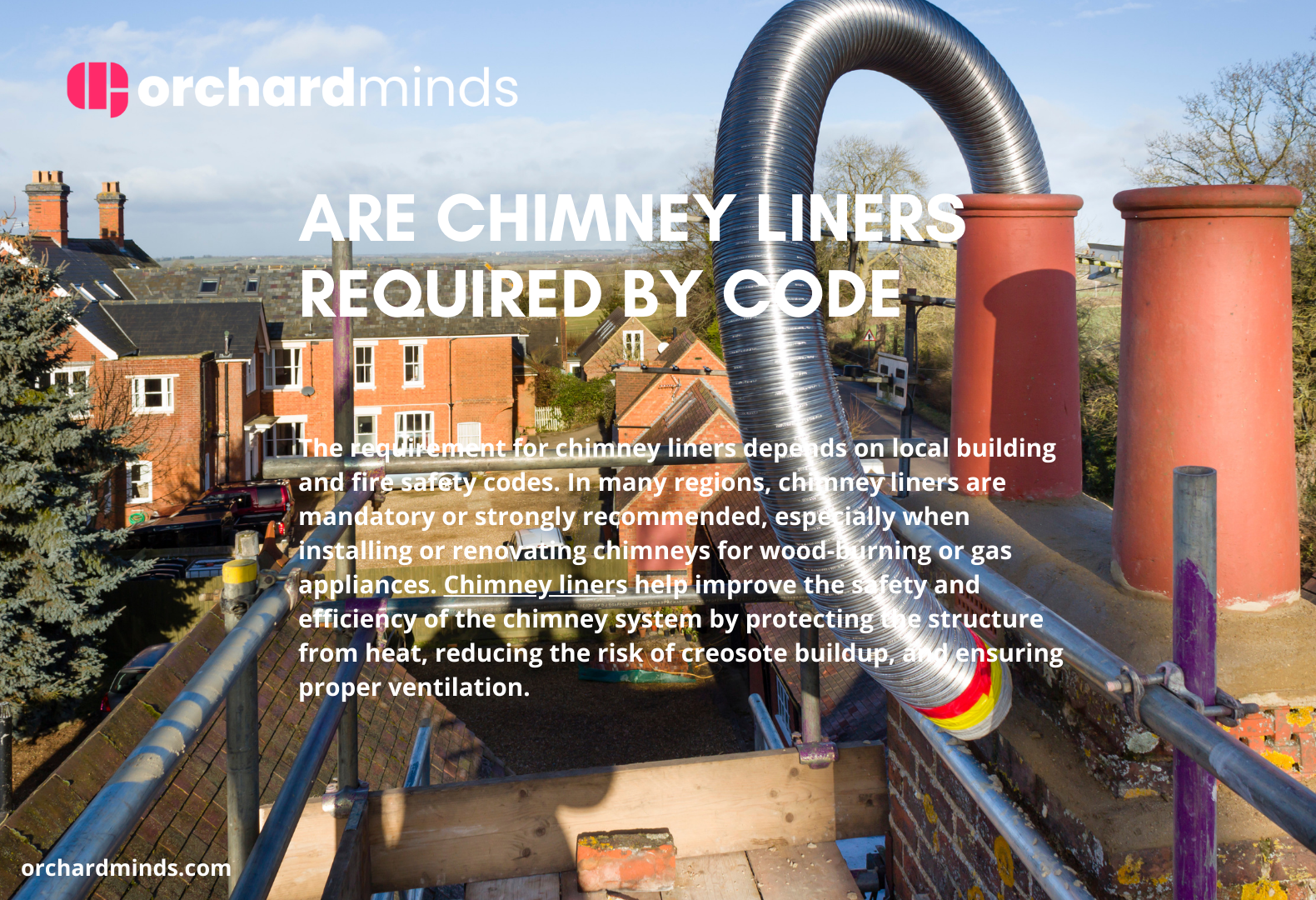

Are chimney liners required by code? The requirement for chimney liners depends on local building and fire safety codes. In many regions, chimney liners are mandatory or strongly recommended, especially when installing or renovating chimneys for wood-burning or gas appliances. Chimney liners help improve the safety and efficiency of the chimney system by protecting the structure from heat, reducing the risk of creosote buildup, and ensuring proper ventilation. To ensure compliance with your specific local regulations, it’s essential to consult with a qualified chimney professional or building inspector who can provide guidance tailored to your area’s code requirements.

The Purpose of a Chimney Liner

The primary purpose of a chimney liner is to enhance the safety and efficiency of a chimney system. It serves several key functions:

- Safety: A chimney liner provides a protective barrier between the chimney’s interior and the home’s surrounding structure. It helps prevent heat transfer to combustible materials in the building, reducing the risk of fires.

- Improved Draft: Liners can enhance the draft or airflow within the chimney, ensuring that combustion byproducts like smoke and gases are properly vented outside, essential for safely operating appliances such as fireplaces, wood stoves, and furnaces.

- Reduced Creosote Buildup: Chimney liners help minimize creosote accumulation in wood-burning applications. This highly flammable substance can lead to chimney fires. Liners maintain more consistent temperatures and smooth surfaces, which discourages creosote formation.

- Durability: Liners protect the chimney’s inner walls from corrosive byproducts and weather effects, extending the chimney’s lifespan.

- Efficiency: A properly sized and insulated liner can improve the heating appliance’s efficiency, allowing it to work more effectively and reducing energy consumption.

- Condensation Prevention: Liners can help prevent the formation of condensation within the chimney, reducing the risk of moisture damage to the chimney structure.

Why You Shouldn’t Use a Chimney Without a Liner

Using a chimney without a liner is strongly discouraged for several important reasons:

- Safety Hazard: Without a liner, the heat generated by your fireplace, wood stove, or heating appliance can directly affect the surrounding building materials. This creates a significant fire hazard, increasing the risk of igniting nearby wood, insulation, or other combustible components within the structure.

- Creosote Accumulation: A chimney without a liner is more prone to creosote buildup, especially in wood-burning applications. Creosote is a highly flammable substance that forms when wood or other organic materials are burned. A lack of a liner can result in irregular temperatures and surfaces within the chimney, making creosote deposits more likely. This poses a significant risk of chimney fires.

- Corrosion and Deterioration: The acidic byproducts of combustion, including moisture and corrosive gases, can damage the chimney’s masonry or inner structure over time. A liner provides a protective barrier, preventing this corrosion and extending the chimney’s lifespan.

- Lack of Draft Control: A liner makes it easier to maintain consistent and proper airflow or draft within the chimney. An unlined chimney may not vent combustion gases effectively, leading to poor appliance performance, including smoke spillage into the room.

- Energy Inefficiency: In heating applications, an unlined chimney can reduce the efficiency of your heating appliance, leading to wasted energy and higher utility bills.

- Environmental Concerns: An unlined chimney may release more pollutants into the environment due to incomplete combustion and poor venting.

Types of Chimney Liners

Several types of chimney liners are designed to suit specific needs and heating appliances. The choice of liner depends on factors such as the type of fuel used, the appliance, and local building codes. Here are the most common types of chimney liners:

Clay Tile Liners:

- Clay tiles are traditional and are still widely used.

- They work well with masonry chimneys and are best suited for open-hearth fireplaces.

- They are unsuitable for high-efficiency appliances or those burning oil or gas because they can’t withstand the corrosive byproducts.

- Metal (Stainless Steel) Liners:

- Stainless steel liners are versatile and suitable for most heating appliances.

- They are highly durable and corrosion-resistant, making them popular for wood, gas, oil, and pellet-burning stoves and fireplaces.

- Available in single-wall and double-wall options. Double-wall liners provide added insulation and safety.

- Cast-in-Place Liners:

- These liners are made by pouring a special refractory cement mixture into the chimney.

- They offer a precise fit and excellent insulation, improving draft and safety.

- Suitable for relining existing chimneys or building new ones.

- Aluminum Liners:

- Aluminium liners are mainly used for specific gas appliances.

- They are lightweight, affordable, and easily installed but unsuitable for solid fuel appliances due to lower heat resistance.

- Hybrid Liners:

- Hybrid liners combine stainless steel’s durability with cast-in-place liner insulation.

- These liners are highly efficient and often used for relining or repairing chimneys.

- Ceramic Liners:

- Ceramic liners are designed for use with high-temperature gas appliances.

- They provide excellent insulation and can withstand extreme heat.

- Concrete Block Liners:

- Concrete blocks can create a liner for large or industrial chimneys.

- They are durable and provide good insulation, making them suitable for high-capacity appliances and commercial settings.

- Polypropylene Liners:

- Polypropylene liners are typically used for highly efficient condensing gas appliances.

- They are resistant to corrosion and designed for specific applications.

- Corrugated Liners:

- Corrugated liners are flexible and often used when relining existing chimneys, especially those with offsets.

- They are typically made of stainless steel and can adapt to various shapes and sizes.

The choice of chimney liner should be based on the specific requirements of your heating appliance, local building codes, and the type of fuel being burned.

Chimney Liner Installations & Repair

Chimney liner installations and repairs are critical for ensuring the safety and efficiency of your chimney system. A properly installed liner protects your home from fire hazards, minimizes creosote buildup, and improves ventilation. If your existing liner is damaged or deteriorating, timely repairs or replacement are essential to maintain your chimney’s structural integrity. Professional installation and repair services are highly recommended to ensure your chimney liner is correctly sized, insulated, and compliant with local building and fire safety codes, promoting a safe and effective venting system for your heating appliances.

FAQs about Are chimney liners required by code?

1. Are chimney liners always required by code?

Only sometimes. The requirement for chimney liners depends on local building and fire safety codes. Some codes mandate chimney liners for specific heating appliances or fuel types. In contrast, others leave it as a recommendation or best practice.

2. What types of heating appliances typically require chimney liners?

Solid fuel appliances like wood stoves and fireplaces often require chimney liners. Gas and oil-burning appliances may also require liners in certain cases, depending on local regulations.

3. Why do some codes require chimney liners?

Codes may mandate chimney liners to enhance safety by preventing heat transfer to combustible materials, reducing creosote buildup, and ensuring proper ventilation. Liners also help protect the chimney’s structure from corrosion.

4. Can I install a liner or hire a professional?

It’s generally advisable to have a professional chimney specialist install or inspect your chimney liner. They can ensure it complies with local codes, is the right size, and is installed correctly.

5. Do I need a liner for an existing chimney with no liner?

Depending on your location and local regulations, you may be required to install a liner if your chimney lacks one. It’s essential to consult local codes and consider the safety and efficiency benefits of adding a liner.

6. Are there specific requirements for liner materials, such as stainless steel or clay tiles?

Codes may specify the type of liner material based on the heating appliance and fuel used. Stainless steel is a common and versatile choice, but clay tiles and other materials may be appropriate in certain cases.

7. What happens if I don’t comply with chimney liner requirements in my area?

Non-compliance with local codes can lead to legal issues, difficulties with home insurance, and, most importantly, safety risks. Following local regulations to ensure a safe and efficient chimney system is crucial.

8. Can I use a liner for a gas-burning fireplace or appliance if it’s not required by code?

Even if not required by code, using a liner for a gas-burning appliance can provide additional safety and efficiency benefits. It’s wise to consult with a professional to determine the best practices for your situation.

9. How often should I inspect and maintain my chimney liner?

Regular inspections and maintenance are essential to ensure the liner’s integrity and performance. The frequency of inspection may vary based on use and local guidelines.

10. Can a damaged liner be repaired, or is a replacement necessary?

It depends on the extent of the damage. Minor issues may be repairable, but significant damage often requires liner replacement for safety and efficiency.