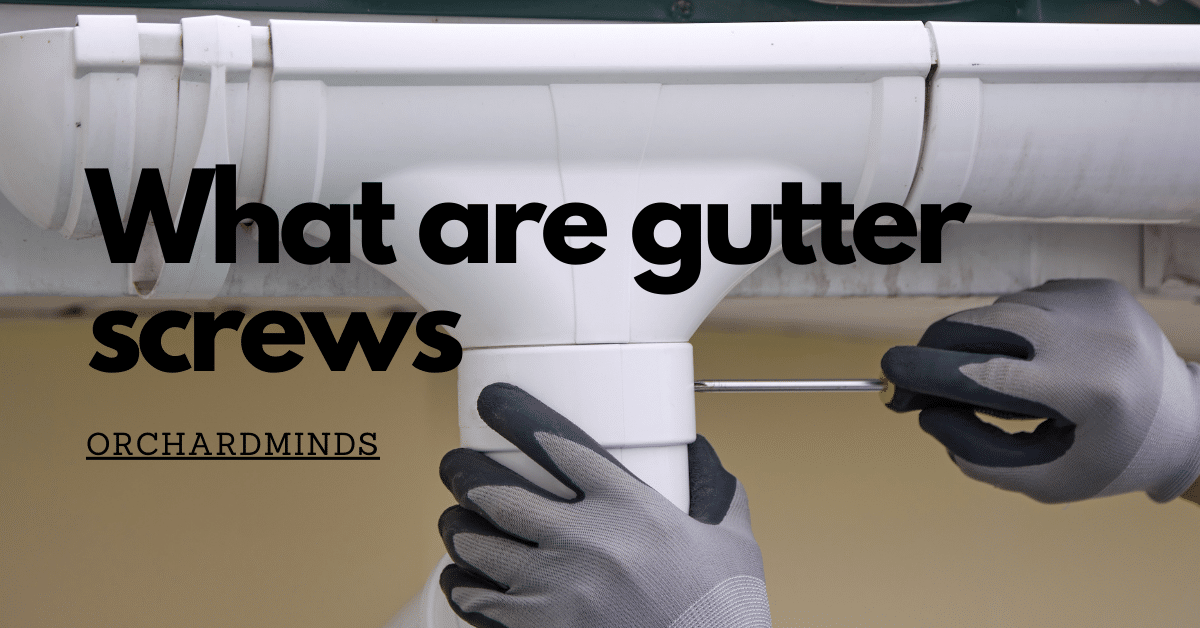

What are gutter screws ? Gutter screws are specialized fasteners designed for the installation and maintenance of gutter systems. These screws play a crucial role in securely attaching gutters to the fascia board or other support structures along the roofline. Typically made from durable and corrosion-resistant materials like stainless steel or coated aluminium, gutter screws provide a stable connection, preventing sagging or detachment over time. Their design often includes features like self-tapping capabilities, allowing them to create their threads during installation.

Gutter screws are integral in supporting the weight of gutters, especially during heavy rain or snowfall, and contribute to the overall effectiveness of the gutter system in directing rainwater away from the structure. Regular inspection and maintenance of gutter screws are essential to address any loosening and ensure the long-term reliability of the entire gutter system.

Gutter Screws

Gutter screws are specialized fasteners designed for securing gutters to the fascia board of a building. These screws play a crucial role in providing stability and support to the entire gutter system. Typically made from durable and corrosion-resistant materials like stainless steel or coated aluminium, gutter screws are resistant to the elements, ensuring a long lifespan and reliable performance. They are essential during both the initial installation of gutters and subsequent maintenance tasks.

The screws are strategically placed to prevent sagging, misalignment, or detachment of the gutters, contributing to effective rainwater drainage and protection against water damage to the structure. Regular inspection and maintenance of gutter screws are advisable to address any loosening over time and to uphold the overall integrity of the gutter system.

Understanding the Purpose and Importance of Gutter Screws

Gutter screws serve a critical role in the proper functioning and structural integrity of gutter systems. Their primary purpose is to securely attach gutters to the fascia board or other supporting structures along the roofline. By providing a stable connection, gutter screws prevent sagging, misalignment, and detachment, ensuring that the gutters effectively channel rainwater away from the roof and foundation.

The importance of these screws lies in their ability to withstand environmental stressors, such as heavy rainfall, wind, and snow loads. Additionally, they contribute to the longevity of the gutter system, reducing the risk of water damage to the property. Regular inspection and maintenance of gutter screws are essential to address any loosening over time, reinforcing their crucial role in preserving the overall functionality and performance of gutter systems.

Types of Gutter Screws

Types of gutter screws vary based on their design, material, and intended use. Common types include:

Self-Tapping Gutter Screws:

These screws have a pointed tip that allows them to create their threads as they are driven into the gutter material. Self-tapping screws are convenient for materials like aluminium and can streamline the installation process.

Hex Head Gutter Screws:

Featuring a hexagonal head, these screws are driven using a hex wrench or drill bit. The hex head provides a secure grip during installation and removal.

Phillips Head Gutter Screws:

With a cross-shaped head, Phillips screws are widely used and easily driven using a Phillips screwdriver. They are a common and versatile choice for various gutter materials.

Gutter Screws with Integrated Washers:

These screws come with built-in rubber or neoprene washers. The washers create a tight seal between the screw and the gutter material, enhancing water resistance and preventing leaks.

Coated Gutter Screws:

These screws are coated with materials such as zinc, galvanized steel, or other corrosion-resistant substances. The coating provides an extra layer of protection, making it suitable for regions with diverse weather conditions.

Long Shank Gutter Screws:

Designed for thicker gutter materials or specific installation requirements, long shank screws have extended lengths to ensure a secure attachment through the material and into the fascia board.

Choosing the right type of gutter screw depends on factors such as the material of the gutter, environmental conditions, and personal preferences. Always follow manufacturer guidelines and local building codes for the most appropriate screw type for your specific gutter system.

Installation Essentials

The installation of gutter screws is a critical aspect of creating a robust and effective gutter system for residential and commercial structures. To begin the installation process, it is essential to plan the layout of the gutter system, considering factors such as the slope, downspout locations, and the type of gutter material being used. Gutter hangers or brackets should be securely attached to the fascia board, providing the foundational support for the gutters.

The choice of gutter screws is crucial, and considerations include the type of screw, its length, and its resistance to corrosion, especially in regions prone to diverse weather conditions. Utilizing self-tapping screws can simplify the installation process by allowing the screw to create its threads as it is driven into the gutter material. It’s important to space the screws evenly along the length of the gutter, adhering to manufacturer recommendations to ensure proper weight distribution and stability. Using a level during installation helps maintain the correct slope, ensuring efficient water drainage towards the downspouts.

Once the gutters are securely in place, additional accessories such as downspouts, end caps, and gutter guards can be attached using compatible screws. Periodic inspection and tightening of screws are essential for ongoing maintenance, ensuring the continued effectiveness of the gutter system in preventing water damage and protecting the structure. Overall, proper planning, choice of high-quality screws, and attention to detail during installation are essential in creating a durable and reliable gutter system that effectively manages rainwater.

Materials Matter

The composition of gutter screws is a critical aspect that directly influences their durability, performance, and resistance to environmental factors. Gutter screws are commonly crafted from materials such as stainless steel, galvanized steel, aluminium, or coated alloys. Stainless steel screws are prized for their exceptional corrosion resistance, making them ideal for areas with high humidity, salt exposure, or corrosive pollutants.

Galvanized steel screws feature a protective zinc coating, enhancing their resilience against rust and corrosion. Aluminium screws are lightweight and naturally resistant to corrosion, making them suitable for various gutter materials. Coated alloys, often featuring zinc or other corrosion-resistant coatings, provide an additional layer of protection, ensuring the screws can withstand exposure to the elements over an extended period. The choice of material is crucial, especially in regions with diverse weather conditions, as it directly impacts the longevity and effectiveness of the gutter system.

Additionally, compatibility between the gutter material and the screws is vital to prevent galvanic corrosion. By selecting gutter screws with materials tailored to the specific demands of the environment and the gutter system, homeowners and contractors can ensure a reliable and long-lasting installation that effectively safeguards structures from water damage. Regular maintenance and inspection of these screws are essential to identify any signs of wear or corrosion, allowing for timely replacement and the sustained functionality of the gutter system.

Maintenance and Troubleshooting: Keeping Gutter Screws Secure and Effective

Maintenance and troubleshooting are pivotal aspects of ensuring the continued effectiveness of gutter screws in a gutter system. Regular inspection is crucial to identify any loose or corroded screws, as they can compromise the structural integrity of the entire gutter system. During maintenance, homeowners or professionals should check for signs of rust or corrosion on the screws, particularly in regions with challenging weather conditions.

Tightening loose screws promptly is essential to prevent sagging or detachment of the gutters, which could lead to water damage to the property. Troubleshooting involves addressing issues such as misalignment, uneven spacing of screws, or damage caused by external factors like falling branches or debris. In the event of any identified problems, it’s important to replace damaged or compromised screws with new ones, ensuring a secure and stable attachment of the gutters.

Gutter screws with integrated washers or coatings can enhance water resistance and prevent leaks, contributing to the longevity of the gutter system. A proactive approach to maintenance and troubleshooting not only safeguards against potential water damage but also prolongs the life of the entire gutter system, providing reliable protection for the structure against the adverse effects of rainwater.